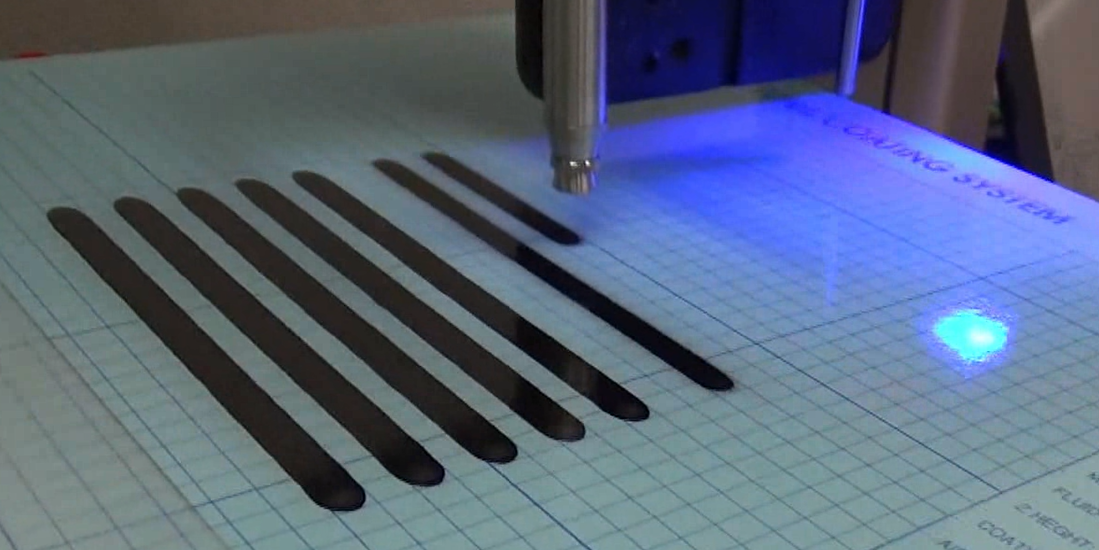

Smallest dots dispenser + Real time monitoring

Twin-air dispenser (Full function type)

This is a high-function model; a top view camera and a laser displacement gauge are mounted on a Twin-air dispenser. Its gap measurement mechanism and nozzle up/down mechanism enable high-precision dispensing.

When a side view camera (optional) is mounted on the dispenser, two cameras allow you to check the dispensing position and the discharge condition simultaneously in real time, so the dispensing quality becomes consistent, and you can set the fine dispensing condition easily.

Features

- Drawing capability of a φ40μm or smaller micro-dot or a fine line of 40μm wide or less.

- Self-suck-back function for preventing a liquid agent from dripping or cobwebbing.

- Discharge capability of up to 1,000,000 mPa.s high-viscosity liquid.

- Integrated machine design in which a top view camera (our unique coaxial optical system) and a laser displacement gauge are incorporated.

- Simultaneous monitoring capability from two directions when a side view camera (optional) is mounted on the machine.

Application examples

- Drawing of a fine electrode pattern with silver paste or cupper paste

- Dispensing of a micro solder dot (φ50μm or less)

- Dispensing of a minute amount of adhesive or high-viscosity resin

Specification

| Minimum dischargeable dot size* | Φ40um |

|---|---|

| Nozzle inner diameter | 25, 40, 70, 100, 150, 200μm |

| Nozzle material | Ceramic + SUS |

| Maximum dischargeable viscosity* | 1,000Pa.s |

| Mounted as a standard part | Top view camera, laser displacement gauge, nozzle up/down mechanism, valve unit |

| Side view camera | Mountable as an option |

| Head dimensions/weight | W168.5 × D137 ×H315 mm 4.9 kg (including a side view camera) |

| Accessories | Dedicated controller |

*The performance cannot be guaranteed because it varies depending on the physical properties of a liquid agent.