Image processing technology

Why is the image processing technology important?

The entire dispensing process (Teaching -> Recognition of a work position -> Alignment -> Dispensing -> Inspection -> Feedback) should be optimized so that the stable dispensing quality can be realized while dispensing is being raised to the higher level and refining is progressing. Therefore, high-performance image processing software is required.

Basic performance of the image processing software exclusively designed for high-precision dispensing

- Creation of a dispensing program

- A complicated dispensing program can be created easily by vision teaching and/or importing of a DXF file.

- Recognition of an image of a work (object to be dispensed to)

The position and shape of a miniaturized work should be recognized at high-speed and accurately. - Automatic alignment (correction of a dispensing position)

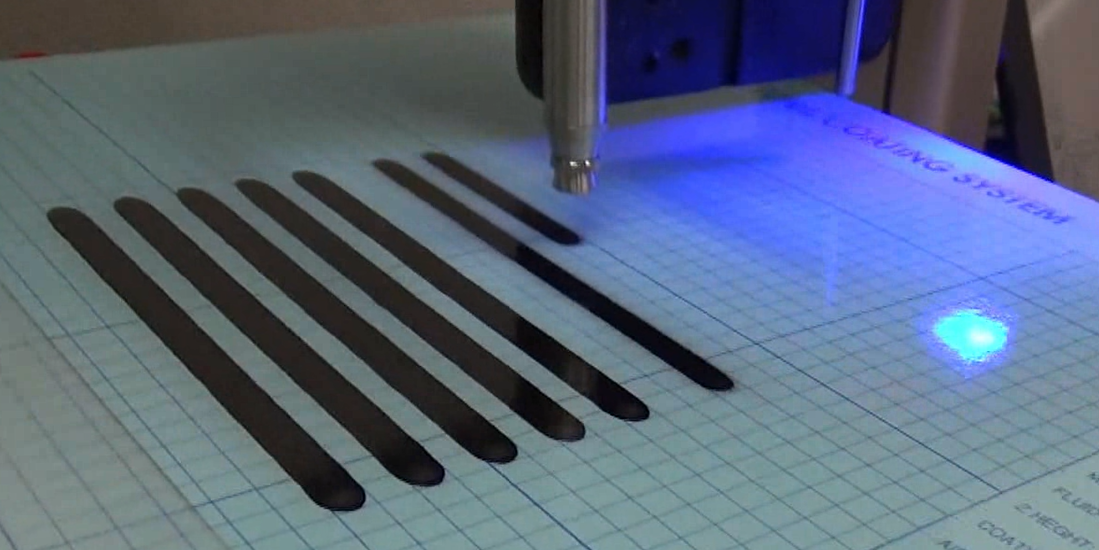

By recognizing an image of a work and laser length-measurement, a dispensing position is corrected automatically, and this allows the corresponding dispenser to dispense to the correct position. - Monitoring of the dispensing condition (by Engineering-Lab original technology)

The dispensed condition is monitored real time with the top view and the side view. - Inspection of the dispensing result and making it into database

The dispense dimension is measured, and then photographs and video files (top view/side view) are saved.

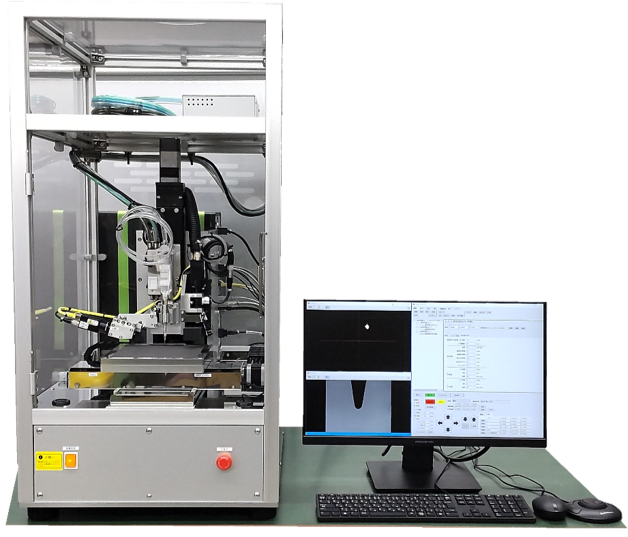

ED20 + Image processing software

Recognition of image of a work + Automatic alignment

Based on an image shot with the top view camera, the most appropriate recognition method is selected according to the characteristics of a work. The image recognition precision can be improved also by optimization of the light and so on.

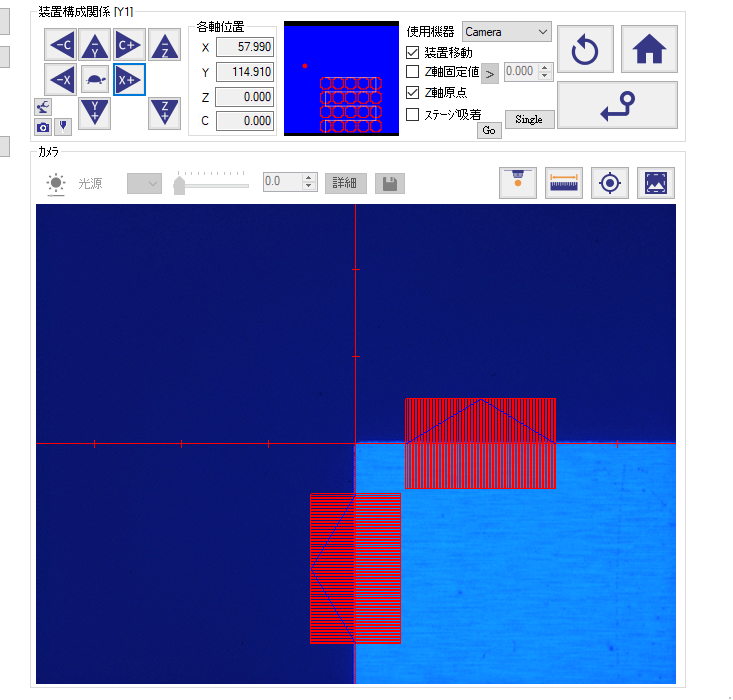

- Template matching

By comparing with a template image (reference image), a more similar image is extracted to recognize the position error/inclination of a work. - Detection of a corner and an edge

Change in brightness of an image is detected to detect an edge and/or a corner of a work. - Automatic alignment

The dispensing position (X, Y, θ) is automatically corrected in response to a position error/inclination of a work. - Height correction by laser length-measurement

Laser length-measurement is performed for the height of a work (one point, desired three points, continuous measurements and so on), and then the Z-axis is automatically corrected to maintain the clearance between the nozzle and the work constantly.

Corner detection

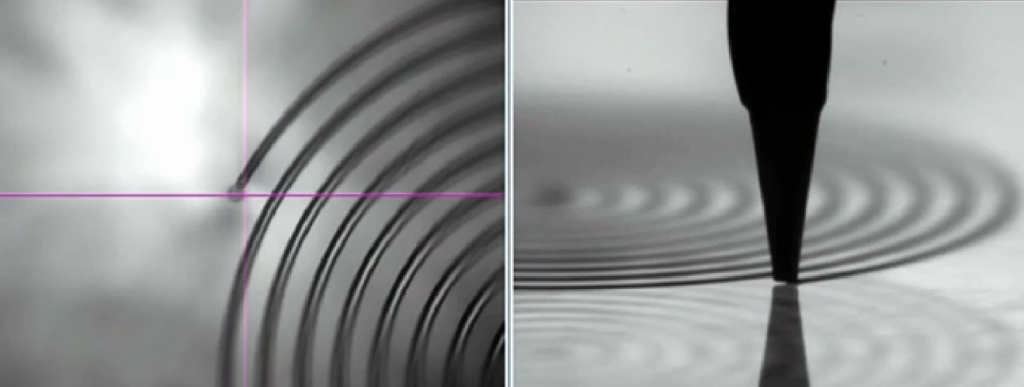

Monitoring with the top view camera and the side view camera + Inspection

The top view camera and the side view camera, both of which are developed with Engineering-Lab original technology, can be driven to improve the dispensing quality extensively.

- Top view camera (Engineering-Lab original technology)

The nozzle coaxial optical system allows you to check an image of dispensing viewed from the top real time, so that you can monitor a variation of the dot diameter and spreading of liquid agent over a work.

You can simply measure some items such as the line width and the distance between two points also. - Side view camera

The side view camera allows you to simply monitor the landed liquid condition as well as the clearance between a nozzle and a work, so that it can improve the conditioning operation significantly. You can check a step and/or protrusion of a work also. - Saving of still images and video files

When you save a video file obtained with the top view camera and the side view camera, traceability information can be obtained easily.

Top view Side view