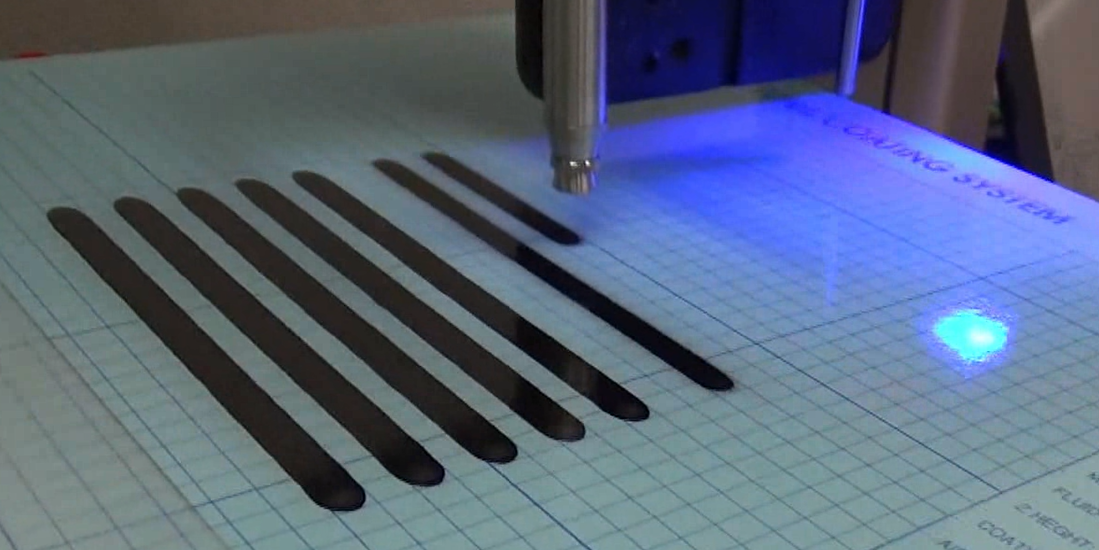

Spiral coater

Main features

- Little scattering enables coating without masking.

Clear painting lines reduce the time and effort required for masking. - A low or middle viscous (10 – 1,500 mPa.s) liquid agent can be coated without diluting it.

Coating of a solventless or aqueous liquid agent as a raw solution reduces the environmental impact. - Coating efficiency: 90 % or higher

Coating efficiency quite higher than that of air spray apparatus leads to reduction of the loss of materials. - Thin film formation at nano level

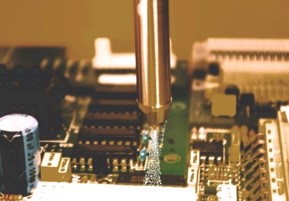

This device is appropriate for thin film forming at nano level to reduce the material costs and shorten drying time. - Atomization in a spiral shape allows an inner wall of a hole or a part having irregular surface to be uniformly coated with conductive ink or coating material.

Application examples

Moisture-proof material, paint, fluorine coating agent, conductive ink and so on

Specification

| Discharging amount (g/min) | 0.1 – 10 | |

|---|---|---|

| Viscosity of a liquid agent | 10 – 1,500 mPa.s | |

| Usable liquid agent | Liquid, solventless (raw material available), aqueous | |

| Coated width | 5-15 mm | |

| Film thickness (μm) | 0.1-100 | |

| Coating speed | 50-300 mm/s | |

| Main application | Film formation, maskless coating | |